Investment in Energy Efficiency Pays Off

- Energy

- KOF Bulletin

There is a lot of talk about the green transformation, but just how widespread are energy-efficient technologies in Germany, Austria and Switzerland? Between 2012 and 2014, more energy-efficient technologies were introduced in Germany and Austria than in Switzerland. This is detrimental on two counts since environmentally friendly innovations often also make sound economic sense.

In the context of National Research Programme 71 (NFP 71 [Managing Energy Consumption]), KOF has joined forces with the Centre for European Economic Research (ZEW) in Germany and the Austrian Institute of Economic Research (WIFO) in Vienna to investigate, among other subjects, the volume of investment in energy-efficient technologies and the associated impact on the environmental record of companies in Switzerland, Austria and Germany. According to the initial results, energy-efficient, more environmentally friendly technologies are not necessarily incompatible with economically efficient production processes.

Different levels of investment propensity

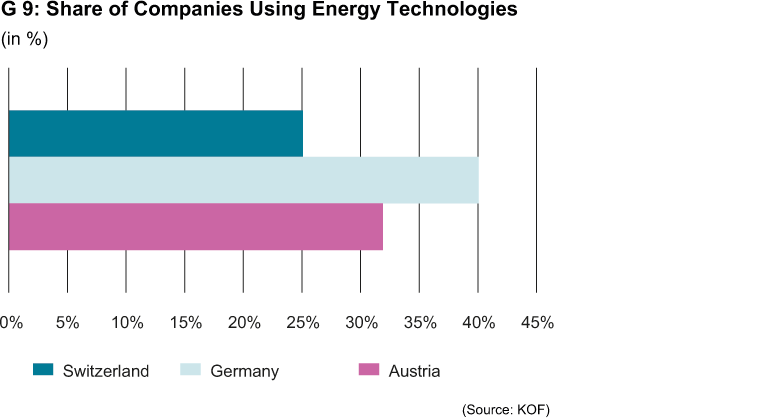

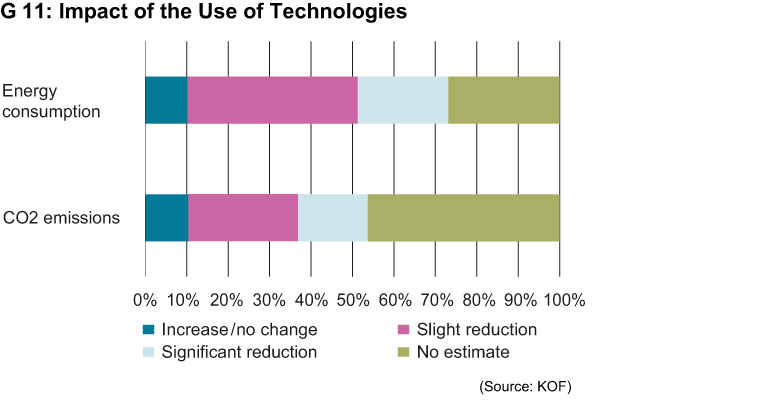

In the period from 2012 to 2014, 25 per cent of the Swiss companies, 32 per cent of the Austrian companies and 40 per cent of the German companies introduced new energy technologies (see G 9). These comprised energy saving technologies and technologies based on new energy sources (e.g. solar, wind). Significant differences also showed up in terms of investment expenditure. In Switzerland, average investments in energy technologies made by all companies amounted to 12.9 per cent of total gross investment expenditure in 2014. The respective figures for Germany and Austria were 17.7 per cent and 19.7 per cent respectively. In the period under review (2012–2014), Switzerland was thus lagging behind its neighbouring countries in terms of its introduction rate and hence its investments in the introduction of energy technologies (see G 10).

Positive environmental impact expected

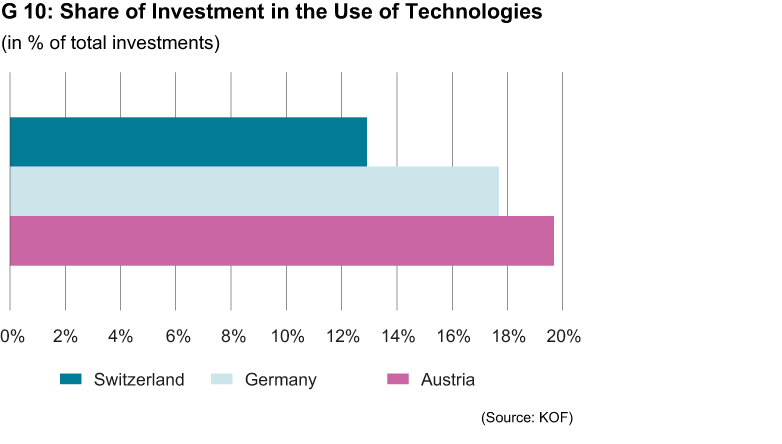

Although the companies’ average energy intensity is relatively low, many among them achieved cost savings after the introduction of energy technologies. On average, 41 per cent of the companies in the three countries stated that their energy consumption per unit/process declined moderately due to the introduction of energy technologies, and 22 per cent even achieved a significant reduction in energy consumption. On top of this, the CO2 balance (per unit/process) improved in most companies. 26 per cent of the companies that introduced energy technologies in the years 2012 to 2014 reported a moderate reduction in CO2 emissions, 17 per cent even a significant reduction (see G 11).1

Economically significant

Porter and van der Linde (1995)2 researched, among other factors, the link between environmentally friendly innovations and corporate success, and established the (Porter) hypothesis positing a positive correlation between the two factors. This conclusion was in contradiction to traditional concepts according to which the factoring in of environmental pollution caused by the production process exclusively raises a company’s costs and has a negative impact on its competitiveness. Initial research results in the context of the NFP 71 study on the correlation between investment in energy-efficient technologies and the productivity of companies based on the data collected in the three countries confirm Porter’s hypothesis for technologies that improve the production process: Investment in energy-efficient technologies and productivity are positively correlated. Consequently, many companies have benefited from investing in these technologies.

At first appearance, this result is not surprising since cost cutting technologies are generally expected to have a positive impact. Hence, the question arises why energy technologies are not more widespread. A glance at the main barriers to their introduction and at the companies’ energy intensity (share of energy costs in turnover) suggests some of the reasons. According to the survey, the main obstacles consist of the cost of adopting the technologies and their long amortisation period. This, however, is predominantly true for companies with high energy intensity. For the majority of companies with low energy intensity, these barriers play a lesser role. It is therefore not surprising that 48 per cent of the companies have never even considered introducing energy technologies.

Consequently, the companies that have already introduced new technologies are generally those with high energy intensity and high awareness of the subject. Increased use of energy technologies, also by companies with lower energy intensity, would be beneficial on two counts. One the one hand, this would improve the environmental record of the economy as a whole and, on the other, cut the cost of these technologies, reduce their amortisation periods and hence increase the technologies’ cost effectiveness; this process could be supported by suitable political measures.

[1] Many companies found it difficult to estimate the environmental impact of the introduction of energy technologies. 27 per cent of the companies were unable to estimate the reduction in energy consumption per unit/process and 46 per cent were unable to quantify their CO2 savings.

[2] Porter, M. E., & van der Linde, C. (1995). Toward a new conception of the environment-competitiveness relationship. The journal of economic perspectives, 9(4), 97-118.

The results of the project are based on a written survey conducted among a representative sample of 5,789 Swiss, 6,374 German and 7,091 Austrian companies. The samples in each country were layered according to company size and industry. The return rate was 31.4 per cent in Switzerland, 36.4 per cent in Germany and 7.6 per cent in Austria. The surveys were conducted simultaneously in all three countries and the same questionnaire was used.

You can find the KOF Working Paper, on which the article is based, Downloadherevertical_align_bottom.

Contact

KOF Konjunkturforschungsstelle

Leonhardstrasse 21

8092

Zürich

Switzerland